OEM CE Certification Bsp Flange Manufacturers - Blind Flanges – Topwill

OEM CE Certification Bsp Flange Manufacturers - Blind Flanges – Topwill Detail:

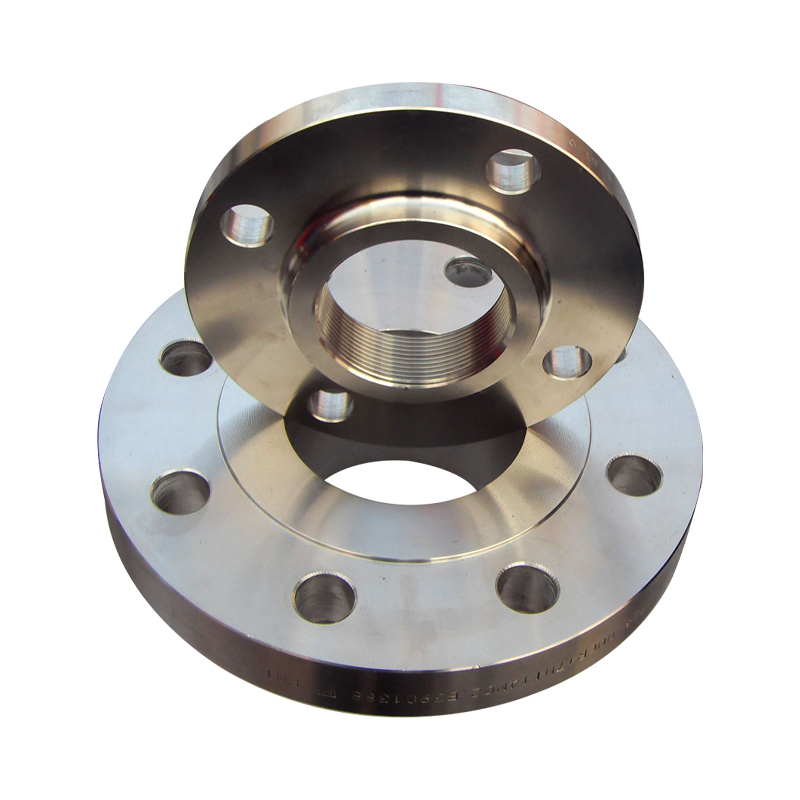

Blind Flanges

product description:

The blind flange is used to close ends of piping systems. It is a kind of round plate with no center hold but with all the proper bolt holes. This blind flange is available in various sizes and materials and is used to provide positive closer on the ends of pipes, valves or equipment nozzles. This flange helps in easy access to a line once it has been sealed. The blind flange is sometimes custom made or machined to accept a nominal sized pipe to which reduction is being made.

Details of Blind flange:

1. Blind flange2. Stud Bolt 3. Gasket 4. Other flange

- Size: 1/2” to 60”, DN 12mm to DN 1500mm

- Pressure class: Class 150 to Class 2,500, PN 2.5 to PN 250

- Facing: RF / RTJ

Material:

- Cabon steel: A105, A350 LF2

- Stainless steel: A182 F304/F304L/F316/F316L/F321

- Alloy steel: F11, F12

Standards, Dimensions & Weight of Blind flanges:

Specifications:

Blind flange is put at the end of pipe or at the junction that would possibly be a future expansion into that direction.

Piping is easier to drill or weld at the construction stage. Once it was in use, drilling or welding will need prolong cleaning especially when the fluid transferred is combustible. For the mean of future extension, either the blind or valve would be used to seal the end.

Advantage of Blind Flanges

- A much more cost efficient way to seal a pipe when doing repairs

- Blind flanges are convenient to install

- They can save a good amount of time and money

Product detail pictures:

Related Product Guide:

Our mission is usually to turn into an innovative provider of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and service capabilities for OEM CE Certification Bsp Flange Manufacturers - Blind Flanges – Topwill , The product will supply to all over the world, such as: Muscat, Mali, Romania, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!