OEM CE Certification B16 5 Flange Suppliers - Welding Neck Flanges – Topwill

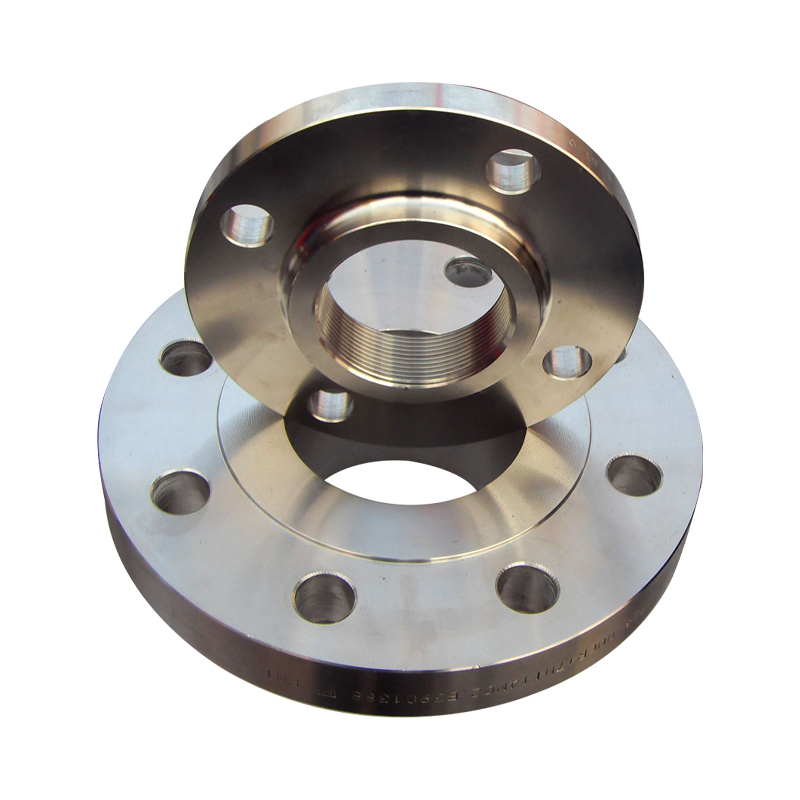

OEM CE Certification B16 5 Flange Suppliers - Welding Neck Flanges – Topwill Detail:

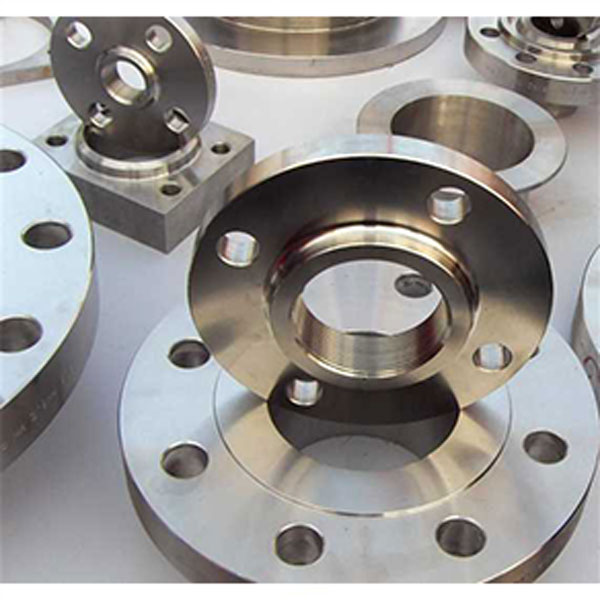

Various process pipeline flanges API6A,ASME B16.5

As a rare material, zirconium is regarded as a more precious aerospace material than titanium due to its amazing corrosion resistance, extremely high melting point, ultra-high hardness and strength and other characteristics. It is mainly exacted from zircon sand and widely used i aerospace, military industry, nuclear reaction and atomic energy fields. With the rapid development of electronics, national defense technology, information industry and emerging materials industry, zirconium chemicals are playing an increasingly important role in the high-tech fields at home and abroad, and the demand is growing rapidly.

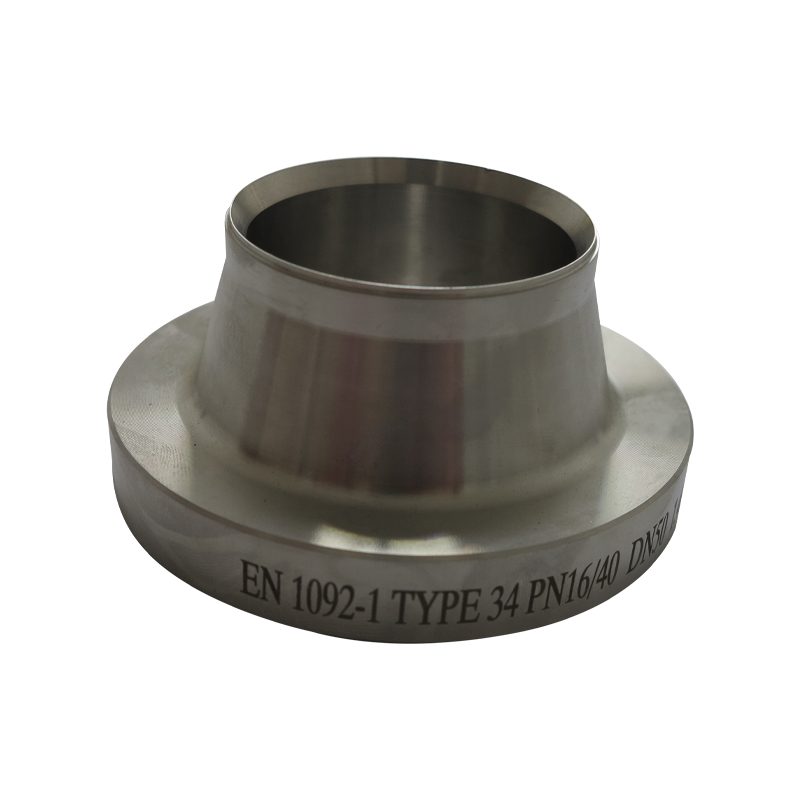

Welding Neck Flanges

product description:

Standards, Dimensions & Weight of WN flange

The welding neck flange is the best designed butt-welded flange of those currently available becuase of its inherent structural value.

Specifications of Welding Neck Flanges:

Size: 1/2” to 60”, DN 12mm to DN 1500mm

Pressure class: Class 150 to Class 2,500, PN 2.5 to PN 250

Facing: RF / RTJ

Material of Welding Neck Flanges:

Cabon steel: A105, A350 LF2, C22.8, S355JR

Stainless steel: A182 F304/F304L/F316/F316L/F321

Alloy steel: F11, F12

Packing: plywood case and plywood pallet

Temperature range:

Viton: -20°C to 200°C

Silicone: -50°C to 230°C

Buna: -30°C to 110°C

EVAC metal seal: -270°C to 150°C

Tube OD sizes: 3/8 to 2 inches

Materials:

Flange: 304 or 316L stainless steel

O-rings: Viton, Buna, & silicone

Fasteners: Wingnut, SureSeal, bulkhead & EVAC clamps

Vacuum range:

Elastomer seal: >=1 x 10^-8 Torr – High vacuum

EVAC metal seal: >=1 x 10^-11 Torr – UHV

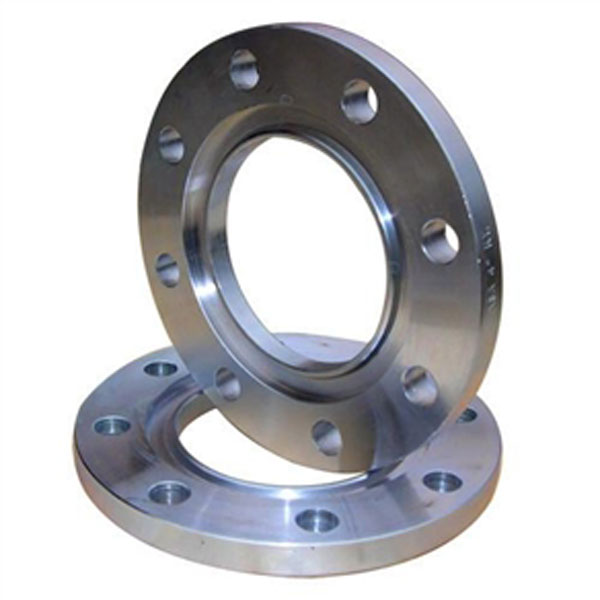

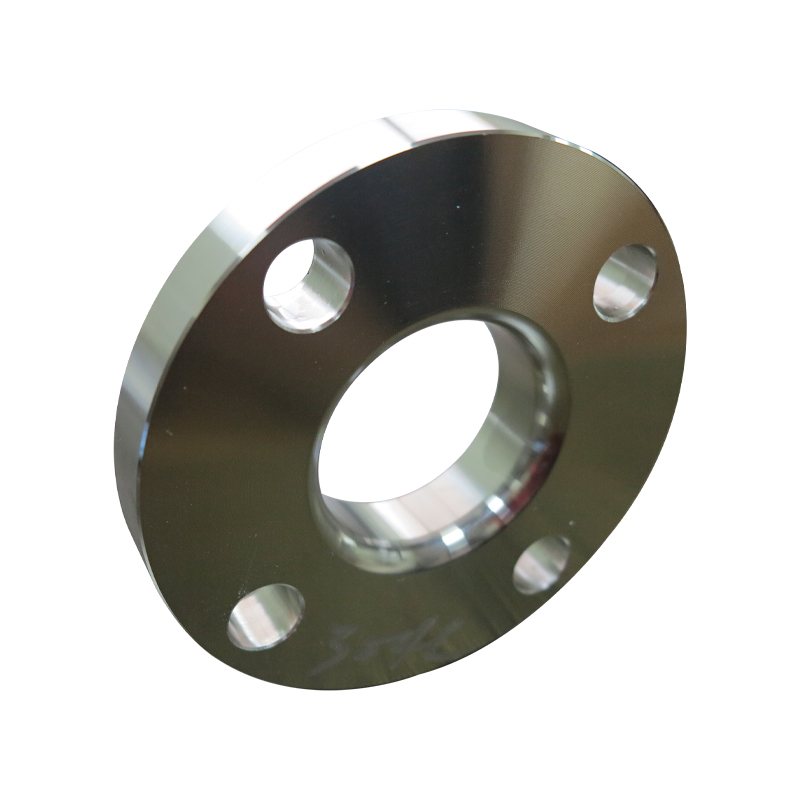

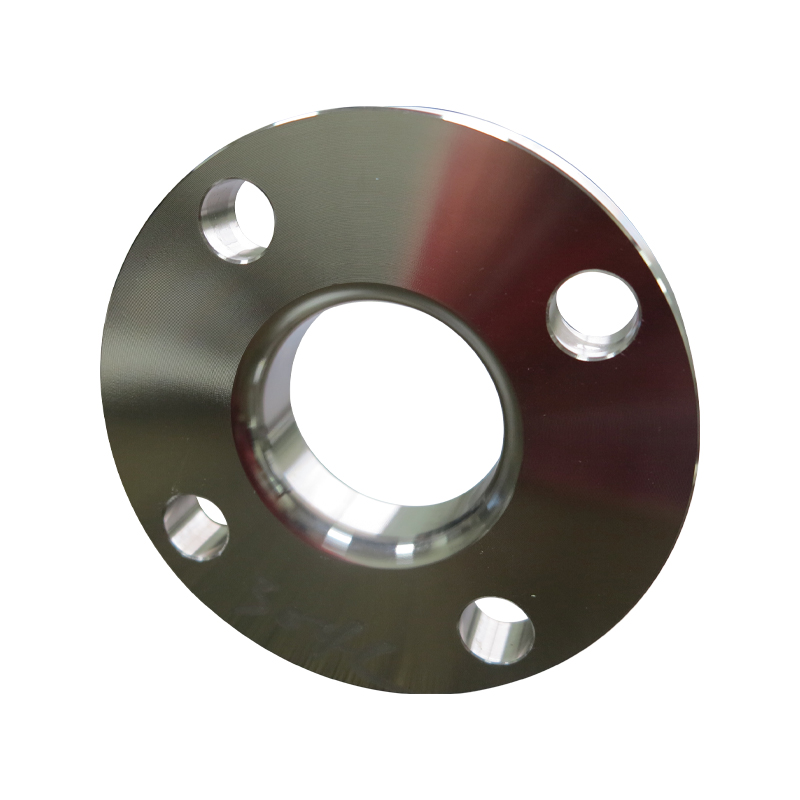

Slip-On Flanges

product description:

Standards, Dimensions & Weight of Slip on flanges:

1. Slip On flange 2. Filled weld outside 3. Filled weld inside 4. Pipe

Material of Slip-on flange:

Slip on pipe flanges in stock include AWWA slip on pipe flanges, ANSI slip on pipe flanges, Pressure Vessel slip on pipe flanges and slip on pipe flanges that match the OD and drilling of ASME flanges.

- Cabon steel: A105, A350 LF2

- Stainless steel: A182 F304/F304L/F316/F316L/F321

- Alloy steel: F11, F12

Packing:

plywood case and plywood pallet

Clad Flange

product description:

Various process pipeline flanges API6A,ASME B16.5Roughing machining of forging before surfacing, 100% PT inspection after surfacing, hardness inspection of surfacing layer, finishing machining of finished products after surfacing.

Flanges base material:

ASTM A105,ASTM A350 LF1, LF2 CL1/CL2,LF3 CL1/CL2

ASTM A694 F42,F52,F60,F70;

ASTM A182 F304/304L,F316/316L;

API 45K,60K,75K,AISI 4130(M),4140,4340,8630(M);

The Inner diameter of cald flange is 38mm-1800mm.

Zirconium Flange

product description:

As a rare material, zirconium is regarded as a more precious aerospace material than titanium due to its amazing corrosion resistance, extremely high melting point, ultra-high hardness and strength and other characteristics. It is mainly exacted from zircon sand and widely used i aerospace, military industry, nuclear reaction and atomic energy fields. With the rapid development of electronics, national defense technology, information industry and emerging materials industry, zirconium chemicals are playing an increasingly important role in the high-tech fields at home and abroad, and the demand is growing rapidly.

Material: Zirconium 702、Zirconium 705

Product detail pictures:

Related Product Guide:

We have many excellent staff members good at marketing, QC, and dealing with kinds of troublesome problem in the production process for OEM CE Certification B16 5 Flange Suppliers - Welding Neck Flanges – Topwill , The product will supply to all over the world, such as: Maldives, Malaysia, Uruguay, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!