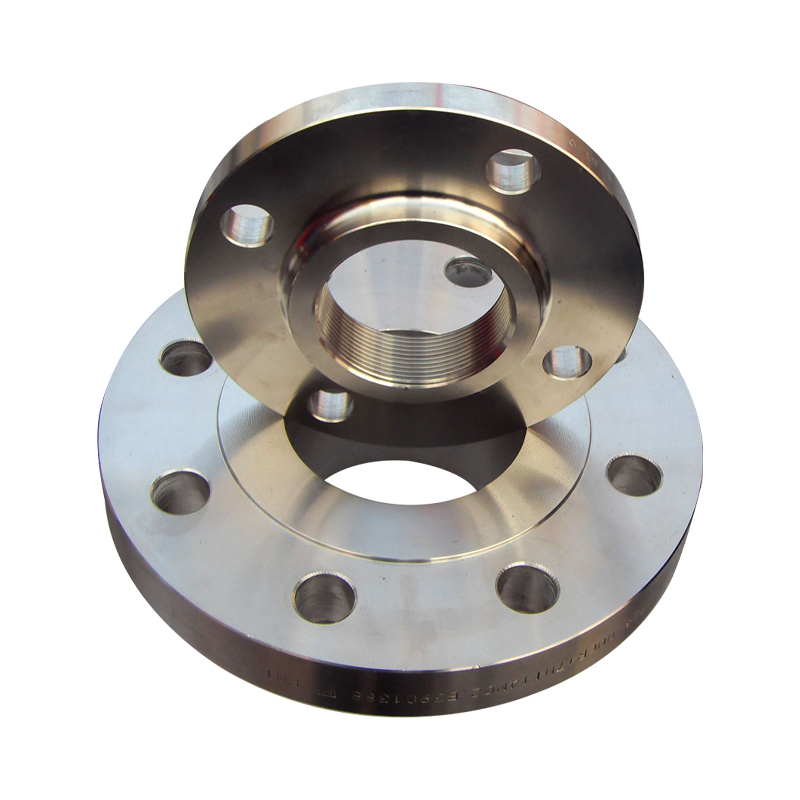

OEM CE Certification 1.5 Inch Flange Manufacturers - Pressed Flanges – Topwill

OEM CE Certification 1.5 Inch Flange Manufacturers - Pressed Flanges – Topwill Detail:

Pressed Flanges

product description:

Why a pressed flange is better:

A pressed flange is 61% lighter than a solid flange, which means also a noticeable reduction of the price. The pressed flange is cheaper than the solid flange. Thanks to its lightness, the pressed flange is easier to install than the solid flange.

Standard:

EN 1092-1 Type 02 (DIN 2642) PN10/16

Material:

-1.4301(304)/1.4307(304L)

-1.4401(316)/1.4404(316L)

-1.4541(321)

-1.4571(316Ti) and some others specialized by customers.

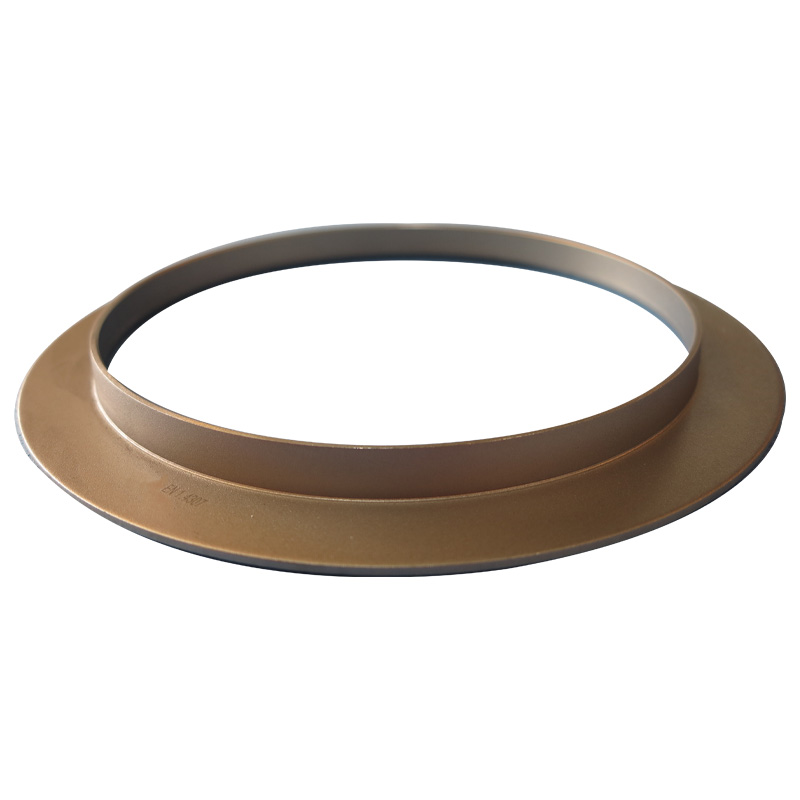

Pressed Collar

product description:

Why a pressed flange is better:

A pressed flange is 61% lighter than a solid flange, which means also a noticeable reduction of the price. The pressed flange is cheaper than the solid flange. Thanks to its lightness, the pressed flange is easier to install than the solid flange.

Standard:

EN 1092-1 Type 02 (DIN 2642) PN10/16

Material:

-1.4301(304)/1.4307(304L)

-1.4401(316)/1.4404(316L)

-1.4541(321)

-1.4571(316Ti) and some others specialized by customers.

Quick Details

product description:

| Place of Origin: | China | Brand Name: | TOPWILL |

| Standard: | DIN/EN1092-1 | Type: | Din Press Flange |

| Pressure: | PN10/16 | Process: | Stamping |

| Product name: | Pressed Flange | Surface treatment: | Ball Blast |

| Color: | Silver | MOQ: | 100 Piece |

| Standard or Nonstandard: | DIN2642 PN10 | Packing: | Plywood Cases |

Products details:

Flange is an item that connects two components of a piping system, which enables its dismantling by non destructive operations, thanks to a circle with holes where the union bolts are matched. The Pressed Flange is the improvement not only in design and functionality but also in price of the traditional Back-Up Flange (we will also call it “solid flange” or “plate flange”). It’s the same product and offers the same technical performance in less weight and less price.

The morphology of the pressed flange increases the water-tightness inside the system, because it has a flap in the interior diameter in contact with the collar, which exerts a pressure on the collar higher than the one exerted by a solid flange.

In summary, the pressed flange has the same behaviour as a solid flange, with more features.

Loose Plate Flange – Dimension ISO

| Loose Plate Flange – Dimension ISO |

| EN 1092-1 Type 02 (DIN 2642) PN10/16 |

| ASTM A 240/A240M: |

| EN10028-7 ( DIN17440 ) |

| AD2000-W2,W9 |

| AISI304/304L ; AISI316/316L; 304/1.4301; Q235 |

| PED |

| Inspection Certificate EN 10204-3.1 |

| DN | PN | Ø ISO | D | K | L | Holes N° | B | N | H | C | ||||||

| 15 | 10/16 | 21.3 | 95 | ±1 | 65 | ±0.5 | 13.5 | ±0.5 | 4 | 24 | ±0.5 | 38 | ±0.8 | 12 | ±0.5 | 3 |

| 20 | 10/16 | 26.9 | 105 | 75 | 13.5 | 4 | 30 | 48 | 14 | 3 | ||||||

| 25 | 10/16 | 33.7 | 115 | 85 | 13.5 | 4 | 37 | 53 | ±1 | 16 | 3 | |||||

| 32 | 10/16 | 42.4 | 140 | 100 | 17.5 | 4 | 46 | 68 | 16 | 3 | ||||||

| 40 | 10/16 | 48.3 | 150 | 110 | 18 | 4 | 54 | 77 | 17.5 | 4 | ||||||

| 50 | 10/16 | 60.3 | 165 | 125 | 18 | 4 | 65 | 91 | 19.5 | 4 | ||||||

| 65 | 10/16 | 76.1 | 185 | 145 | 18 | 4 | 81 | 108 | ±1.5 | 21.5 | 4 | |||||

| 80 | 10/16 | 88.9 | 200 | 160 | 18 | 8 | 94 | 123 | 21.5 | 4 | ||||||

| 100 | 10/16 | 114.3 | 220 | 180 | 18 | 8 | 119 | ±1 | 141 | 22 | ±1 | 4 | ||||

| 125 | 10 | 139.7 | 250 | 210 | 18 | 8 | 145 | 168 | 22 | 5 | ||||||

| 150 | 10 | 168.3 | 285 | 240 | 22 | 8 | 173 | 192 | 26 | 5 | ||||||

| 200 | 10 | 219.1 | 340 | 295 | 22 | 8 | 225 | 245 | 28 | 6 | ||||||

| 250 | 10 | 273 | 395 | 350 | 22 | 12 | 279 | 295 | 31 | 6 | ||||||

| 300 | 10 | 323.9 | 445 | 400 | ±0.8 | 22 | 12 | 329 | 345 | 34 | 6 | |||||

Content of the steel seal:

Font size:4-5mm

According to different specifications and models, the position of the steel stamp will be different, but the content logo will not change

DN15-DN100 : PN10/16 ; DN125-300 : PN10

Markings :

We mark our pieces to offer information about the characteristics of each product: heat number, grade, lot number, etc.

Packaging & Delivery:

| Selling Units: | Single item | Single package size: | 1200X800X600 cm |

| Package Type: | Plywood Cases. |

Lead Time:

| Quantity(Pieces) | 1 - 50 | 51 - 500 | 501 - 2000 | >2000 |

| Est. Time(days) | 3 | 7 | 10 | To be negotiated |

Transport: By ocean/By air

WHAT CAN WE DO FOR YOU?

1. Factory outlet price;

2. Small order is acceptable, even 1 pc;

3. Samples are free and the cost will be returned when placing bulk orders;

4. Fast delivery within 15 days;

5. 100% inspection for all the products;

6. Refundable in case of bad quality;

7. Quick response at any time;

8. After sale service 24/7.

Product detail pictures:

Related Product Guide:

With a sound business credit, excellent after-sales service and modern manufacturing facilities, we have earned an excellent reputation among our customers across the world for OEM CE Certification 1.5 Inch Flange Manufacturers - Pressed Flanges – Topwill , The product will supply to all over the world, such as: United Arab emirates, Sydney, Ecuador, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant skilled knowledge, to develop advanced production equipment and production process , to create the first-call quality solutions, reasonable price , high quality of service , quick delivery , to offer you create new value .

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!